Home » CLD Technology

Acoustic Signature CLD: Constraint Layer Damping

Constraint Layer Damping’ (CLD) is a mechanical engineering method for the absorption or minimization of vibrations. In audio components CLD technology is usually implemented by using sandwich designs that ’embed’ a damping material layer between materials that do not themselves have sufficient damping properties. A cartridge will only track a record unaffected, if it finds a ‘quiet’ surface without resonance interferences. Accordingly, it is necessary to develop ‘vibration-free’ chassis and platter designs – this must be done in addition to the resonance-reducing measures for motors, drive and bearing construction.

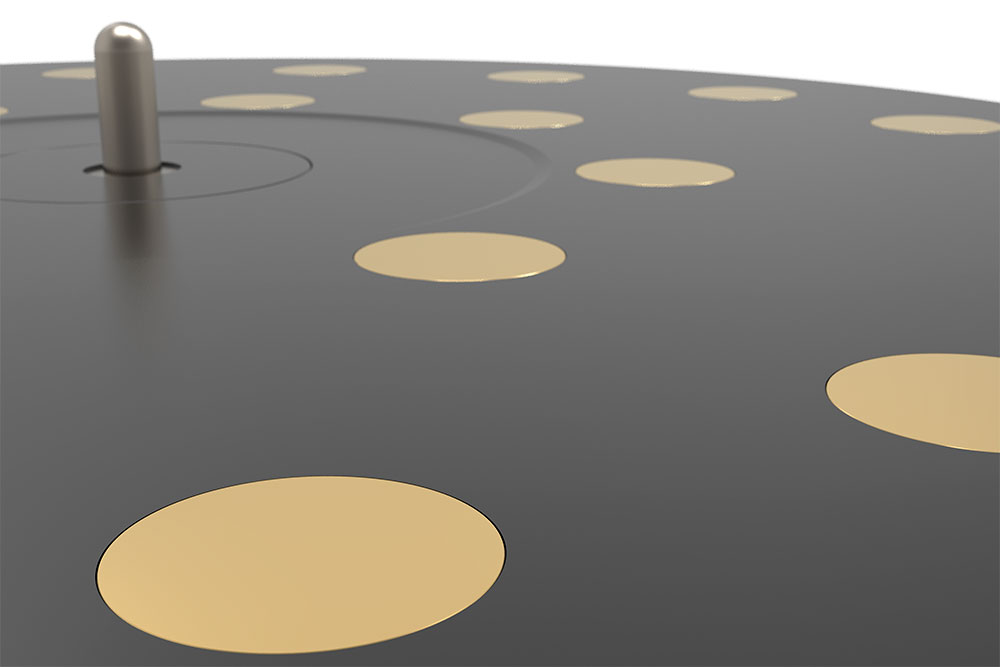

In order to achieve this, we already extended the typical CLD technology approach more than 20 years ago. Beyond the classic sandwich construction, we presented an absolute novelty to the high-end world: the Acoustic Signature ‘silencer’ platter, which immediately set new standards in vibration absorption. Our ‘twin-track’ CLD approach, which is mainly used in our high-mass turntables, is still unsurpassed in its effectiveness.

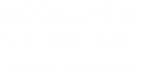

In the course of planning and developing our NEO product line, we have been working intensively on improving our CLD concept. First, our tests led to an optimized material combination consisting of two layers of a special aluminum alloy and an intermediate brass layer. Second, this also led to a new arrangement as well as an adjustment of size, weight and position of our ‘silencer’ brass bolts when implemented in our platters.

In addition, we had to ‘sensibly’ pair the two CLD tools described above with the NEO chassis to maximize the effect. The elaborate material experiments and listening sessions were worth the efforts: in our NEO turntable series we have succeeded in taking the interaction of all technologies to a stunning new level! A rigid, yet energy-absorbing chassis based on finite element design principles, and our new CLD approach creates unbeatable units in terms of resonance behavior.

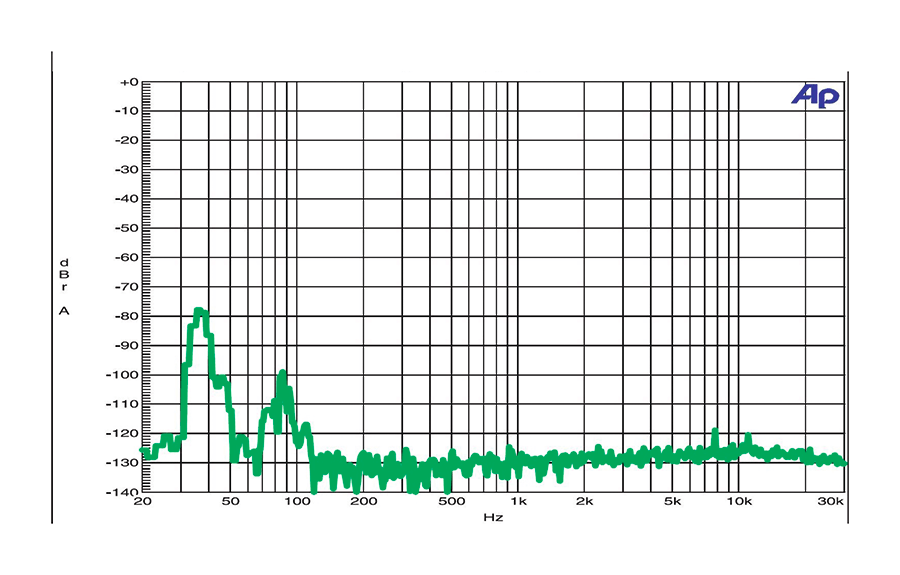

The CLD technologies that we implement in the Acoustic Signature NEO turntable generation have clearly exceeded our metrological expectations and also show off in terms of sound performance – with an even blacker background, larger imaging, increased transparency and, above all, breathtaking musicality.

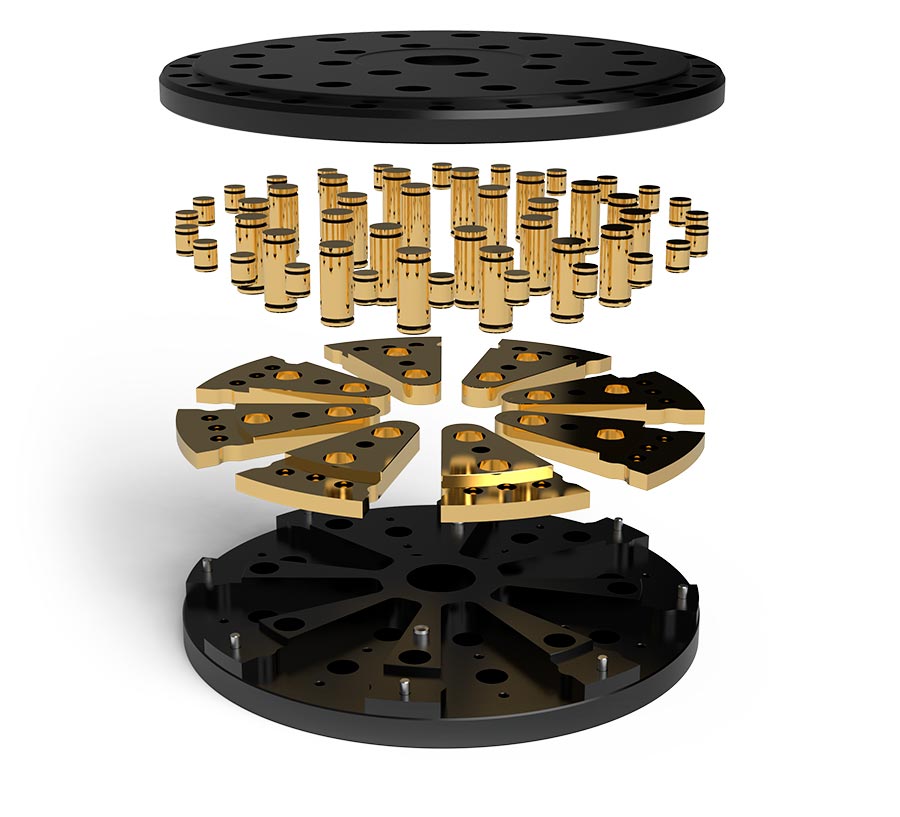

Silencer

The Silencers absorb and reduce vibrations whilst the vinyl disk is playing and you are listening. So, where do the vibrations come from, that we so wish to remove from the platter?

There are several sources. First, the cartridge needle itself, playing a record causes vibrations and resonance in the vinyl, due to the movement of the needle tracking the record groove. It’s easy to check by simply turning the volume down on your amplifier, you can still listen to the music directly from the needle/vinyl with your ear close to it. The needle is actually putting vibration back into the record as it tracks the groove, causing vibration in the whole vinyl record. This leads to ‘micro’ mistracking of the cartridge, when picked up by the needle alongside the actual signal you want from the track, with a very small time delay between the two. The Silencers in the platter absorb some of this unwanted vibration and improve the sound reproduction dramatically.

The second source of vibration is air waves hitting the platter and turntable body from your loudspeakers whilst you’re listening to music. Your cartridge/stylus doesn´t care where movement comes from, be it the grooves or other vibrations. Your cartridge simply produces an electrical signal when vibrating and all vibrations coming through the turntable will result in unwanted signals, resulting in a loss of detail resolution and imaging from your precious vinyl records. The Silencers absorb these unwanted vibrations, leading to a huge improvement in sound fidelity, improving your listening experience.

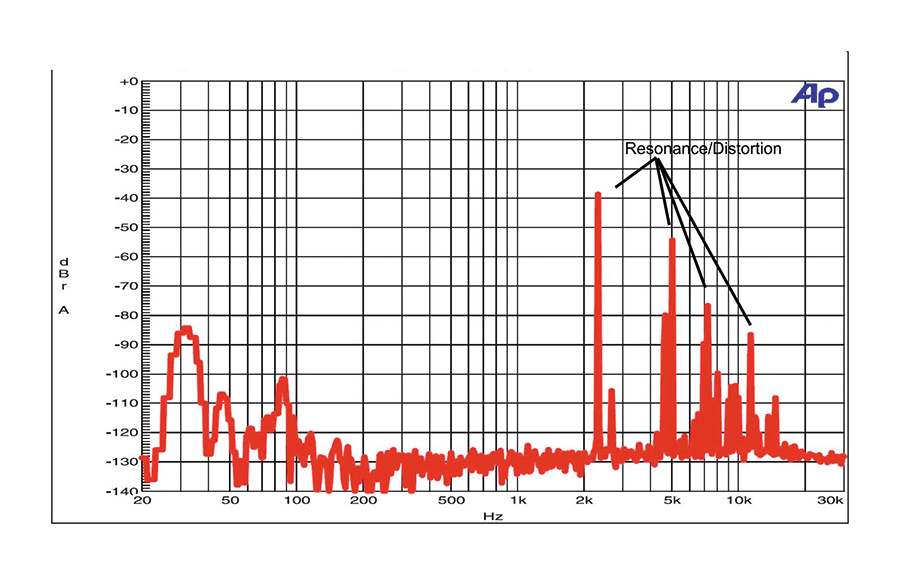

50 mm platter without Silencers