Home » DTD Technology

Acoustic Signature DTD: Duration Diamond Bearing

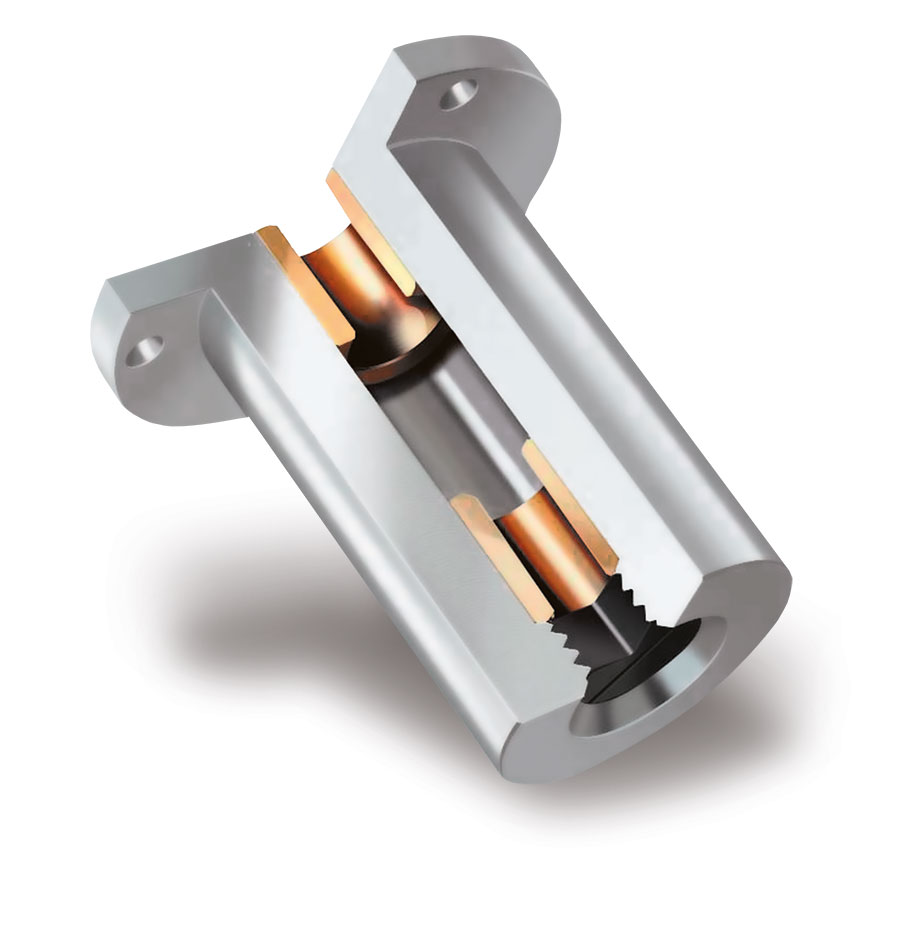

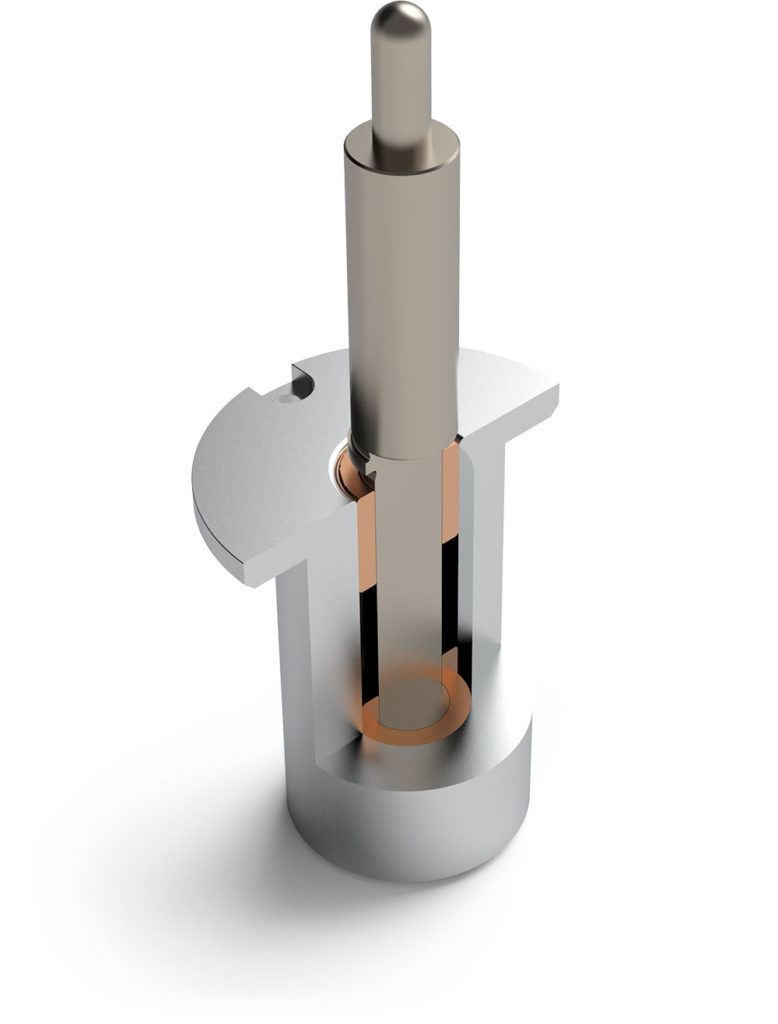

The bearing is the heart of every turntable. Although the bearing design is of such great importance, its development – from the view of physics – is often characterized by imprecise to wrong approaches. Any conventional bearing that is confronted with a heavier platter is extremely sensitive in terms of handling. It also faces a mechanical challenge that is mainly to be found in the contact area of the thrust plate and bearing ball. In other words: the combination of the high platter weight and the very small ball surface causes an enormous pressure in the very small contact area, which simply pushes the lubricating oil away.

The result: too much friction, too much noise, too much vibration and rapid wear. Analogists seeking salvation in an ‘inverted bearing’ are misguided by a marketing trick: the main source of noise within a conventional bearing design is located at the pivot point of the platter axis and the thrust plate, about 4 inches away from the record. By inverting the bearing, this noise source is taken closer to the platter direct below the vinyl surface and thus into the activity area of the cartridge – definitely not a good idea. Moreover, this ‘reversal’ causes a veritable lubrication problem thanks to gravity: the oil is floating away at the contact surface.